HUBS is known for on-demand manufacturing all across the world. Their manufacturing capabilities range from CNC machining to 3D printing. In 2021, HUBS (previously named 3D HUBS) was acquired by Protolabs. mHUB recently chatted with Filemon Schoffer, CCO of HUBS, about the acquisition and their experience being mHUB members.

Hubs has been very successful in making a wide breadth of manufacturing services available at highly competitive prices. Protolabs saw that by combining their in-house velocity with the far-ranging capabilities of Hubs’ manufacturing network, we could truly become a one-stop shop for custom prototypes and production parts.

Where did the original idea and value proposition start? What problem was being solved?

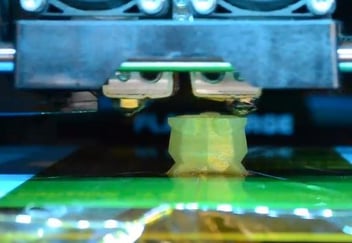

We started with the mission of democratizing the production of custom parts by giving the world easy access to local 3D printing. Once we had succeeded in building the largest distribution network of 3D printing providers, we shifted our business to focus on creating a manufacturing solution for the professional engineer and expanded our services to include CNC machining, sheet metal fabrication, and injection molding.

We want engineers to focus on what they do best - developing products - and spend less time on finding the best option for manufacturing their parts. Our network makes production capacity constantly available and there is never a part too complex or a quantity too low to produce. Engineers can now turn to one platform to order the exact parts they need whenever they need them.

In the early days, how was the network of manufacturing partners built?

We designed an ‘unlock your city’ campaign that went completely viral.

In the early days, to keep our heads above water from an operational standpoint, we decided to close the website globally and only open those areas that had enough suppliers – so we actually had something to ‘sell’. We marketed this as an ‘unlock your city campaign’ where we would require a minimum of 25 local suppliers to sign-up before opening up the website. Given how connected the 3DP community was, this went viral quickly, and we had over 20,000(!) suppliers sign-up within two years.

From 2019 – 2020, HUBS (3D Hubs at the time) was an active member of the mHUB community, operating out of mHUB to help establish a U.S. presence. What mHUB resources were most helpful to the company at that time?

The location was ideal for a manufacturing-as-a-service startup, set in the heart of Chicago, a city we see as the center of innovation for digital manufacturing. But beyond the physical resources provided, the community stood out as a real benefit of mHUB. It was motivating to work alongside a group of like-minded companies to accelerate manufacturing. We actually got a few customers out of it as well. ;)

What have been the most positive outcomes since the acquisition?

The best part of the acquisition has been working together towards a shared vision. In a fragmented industry, no one is serving the customer from end to end. Engineers have to find different specialized manufacturing solutions for their needs. The integration is fundamentally about serving our customers better, and we’ve been enjoying the whole process of teaming up to create the number one digital manufacturing solution in the world.

Is there a story that touches on a pivotal moment or decision that helped shape the company of today?

Our vision has always been to use digital technology to democratize access to world-class manufacturing capacity.

We originally started as a 3DP peer-to-peer network, directly connecting suppliers to customers, in a similar style to how Airbnb works today. We quickly realized that our approach wasn’t sustainable–we created the world’s largest network of 3D printing services and there wasn’t anywhere to go from there. We hit a growth ceiling and couldn’t push further with our ultimate mission of improving the manufacturing process for engineers. We radically changed course, four years in.

We explicitly started to target users that would get the most value out of our service: engineers. We expanded our services beyond 3DP, adding CNC, injection molding, and sheet metal services. We changed our name from 3D Hubs to Hubs to reflect the new scope of our business model. Instead of the peer-to-peer approach, we went for smart-matching technology, directly linking customers to available capacity – more like Uber than Airbnb.

It was a risky pivot but our growth 10x-ed not long after.

Do you have any advice for early-stage or growth-stage companies on being acquired?

Judge the buyer not only by the price they’re willing to pay but by what it means for your customers and service. For us, Protolabs’ services were complementary to the services we offered. So combining the two companies dramatically improved the service for our customers, allowing us to become a true one-stop-shop, the category killer in on-demand manufacturing.

How has the additive manufacturing industry changed since HUBS first launched in 2013?

3D printing has evolved from a mainly prototyping solution into a viable technology for low-volume production for functional end parts. We are seeing more and more big orders placed for 3D printed parts on our platform and the continuing rise of HP’s MJF technology is a good reflection of this trend.

What excites HUBS about the future of additive manufacturing?

It is getting easier to produce highly complex geometries with advanced material composites, at ever more competitive pricing. This is opening up new manufacturing possibilities that have been impossible to unlock with traditional technologies.

Learn more about HUBS. If you are a budding entrepreneur looking for a vast community of innovators, check out mHUB's membership options.