Plastics Lab

Shape, form, bend, and inject plastic materials to bring new product concepts to life.

Plastics Lab Overview

Having access to an extensive range of materials makes iterative prototyping possible. Using injection molders, line-bending machinery, and other fabrication equipment, members can create just about anything they can imagine. A member favorite is the UV Ink printer, which can print customized color and designs on just about any surface.

[Plastic Lab] General Information

Plastics Lab

Cold work and hot form various plastics.

Band Saw

Max. Material Thickness: 6"

Throat Depth 13-5/8"

93.5" Bandsaw Blade

1hp

Desktop Injection Molder

.125" nozzle

1 cubic inch/17cc shot

manually operated

17g of pp per shot

Formech Vacuum Former 686

24" x 24" raw material

22" x 22" working area

1/4" material thickness

12.8" draw

Injection Molder

8" x 11"

800°

12000 psi

6 cu in/4oz shot

semi-automatic

Line-Bending Table

48" working width

1/4" thickness

dual heating elements

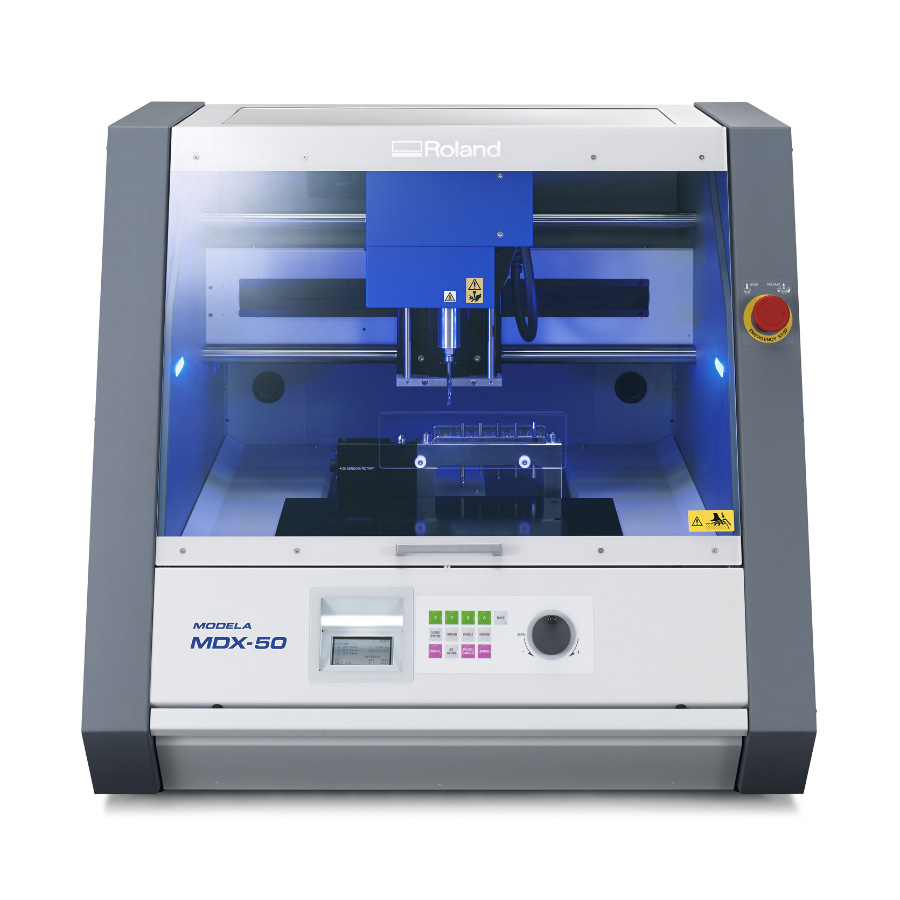

Roland MDX-50

Mill Circuit boards

15.80"x12.00"x5.315"

4500-15000rpm

6 ATC

auto z sensor

Roland UV Ink Printer

Color print on any substrate with undercoat and overcoat

Tour the Prototyping Lab

Come see the 11 prototyping labs for hardtech product development. Schedule your visit today!